Tortilla Equipment

AM TORTILLA PRODUCTION LINE

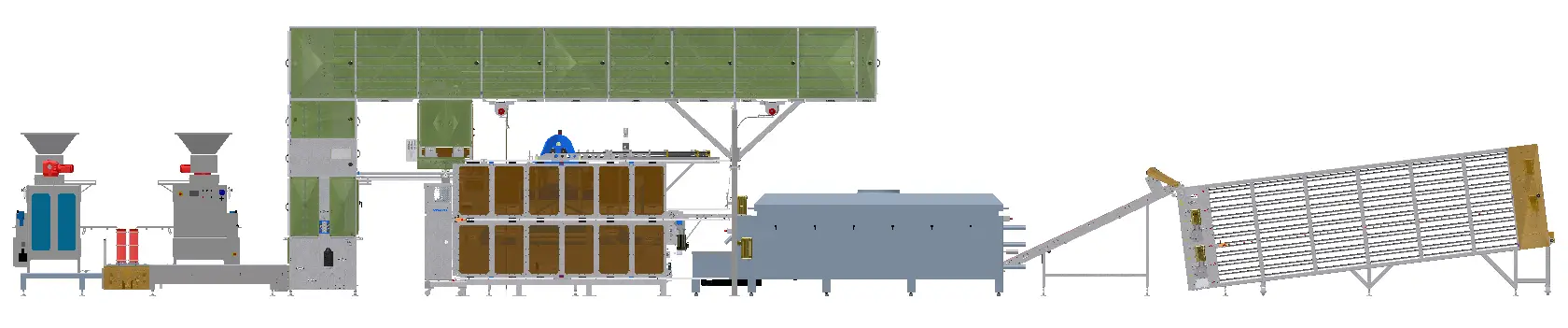

MIXER – Horizontal mixer with tilt bowl dump. Spiral mixers with removable bowls also available.

AUTOMATIC CHUNKER AND DOUGH ELEVATOR CONVEYOR – Reduces labor and lift-related injuries with automated mixing, elevating and discharging.

DIVIDER / ROUNDER – Accurate dough dividing and rounding are critical to consistent tortilla size and quantity. Available up to 12 wide and 36,000 pieces per hour.

MULTI-TIER BASKET PROOFER – The resting and fermentation of the dough ball is accomplished in a controlled environment. Temperature and humidity, as well as proof time are critical to quality tortilla production. Each dough formula is different and proofers are typically designed for individual proofing requirements.

AUTOMATIC DOUGH BALL LOADER – Provides accurate placement of dough balls on the hot press infeed belt.

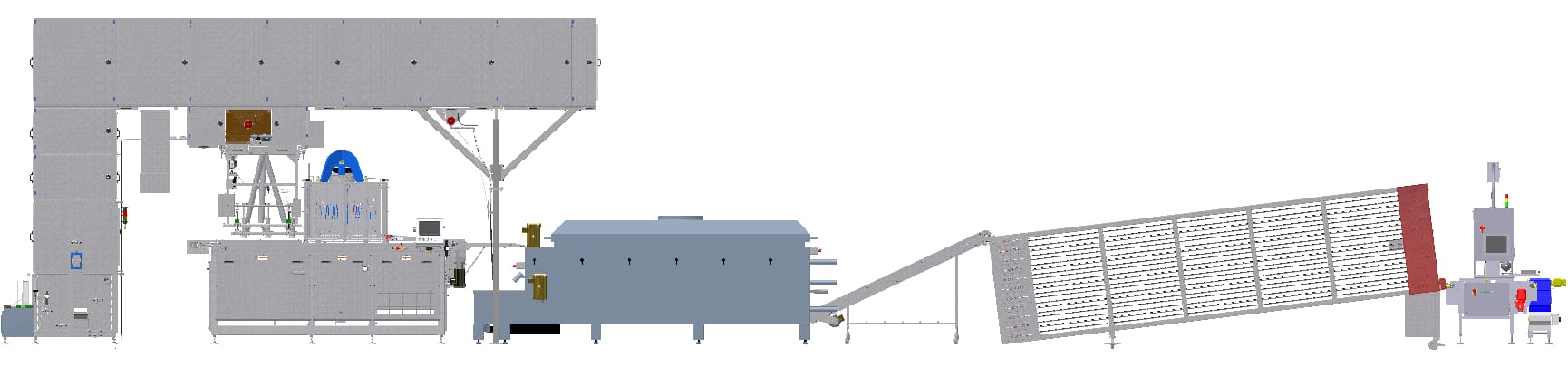

INDEXING OR RECIPROCATING HOT PRESS – Temperature, pressure and dwell time are fully adjustable for your needs and process. Manual or PLC control systems are available.

We currently offer 42” for indexing and 39” by 45” and 54” by 54” for continuous. Other sizes please call the factory.

OVEN – Formed tortillas are conveyed into a multi-tiered gas-fired oven. Supplied with automatic temperature control and a variable speed drive system.

VACUUM TRANSFER CONVEYOR – Vacuum style incline transfer conveyor moving tortillas to cooling conveyor.

COOLING CONVEYOR – After baking the product must be brought to room temperature prior to packing. Ambient or forced air cooling.

TORTILLA COUNTER STACKER – The number of lanes required and product sizes are designed to customer specification. Stack height is fully adjustable.